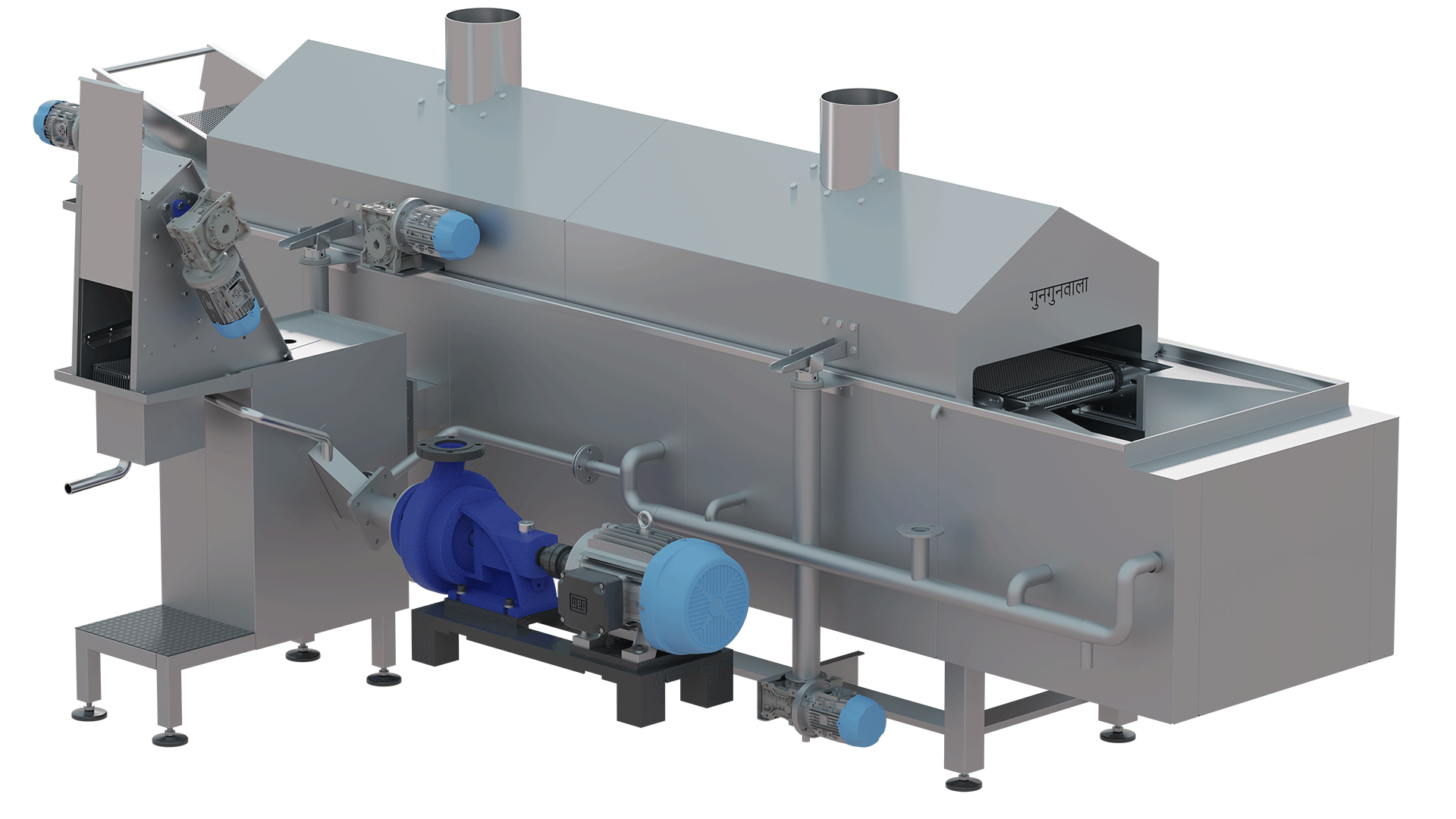

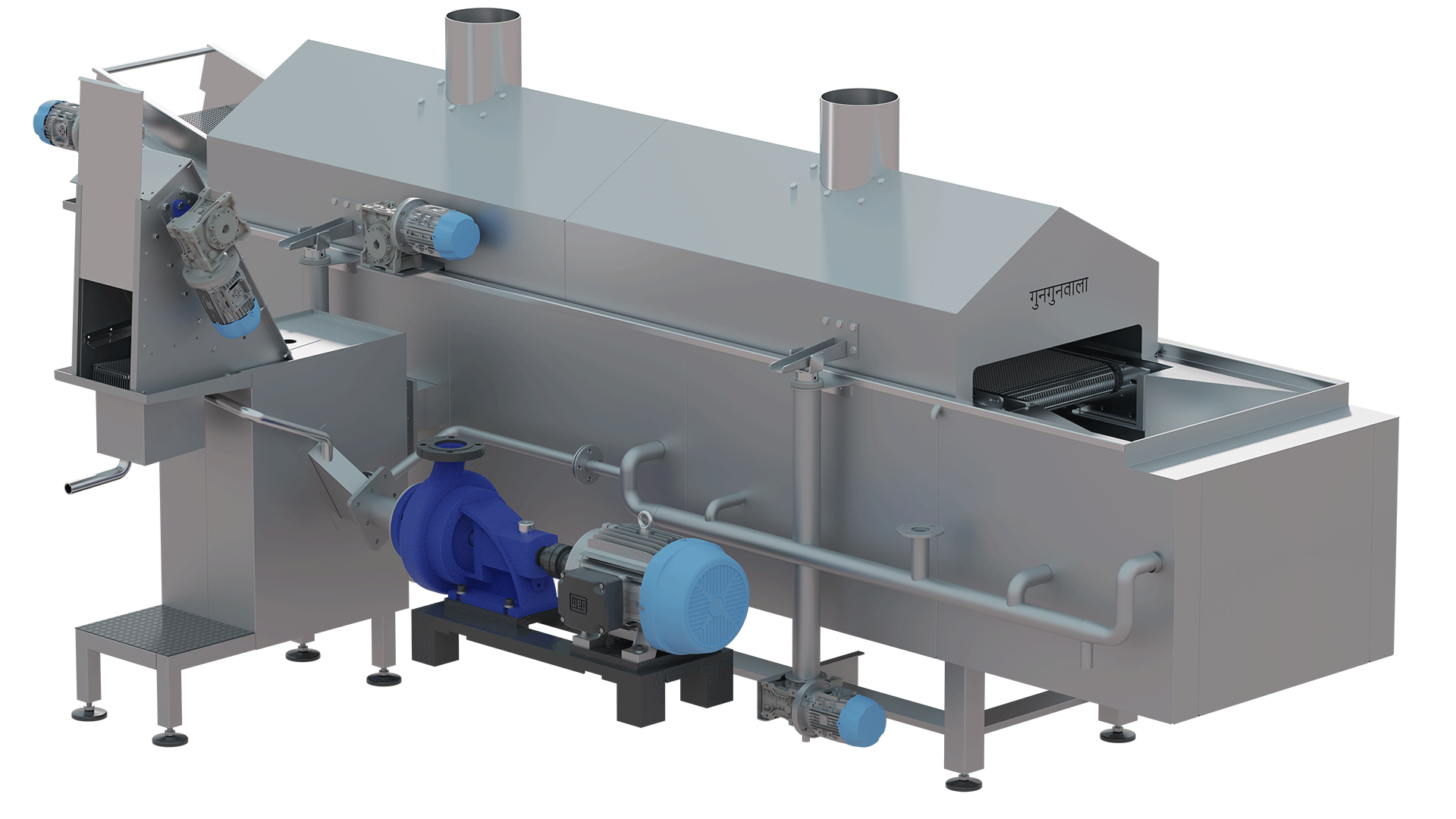

Gungunwala, a renowned company in the manufacture of the equipment to produce snacks, unveiled its new Continuous Dal and Snacks Fryer model. Being a well known manufacturer, supplier and exporter at Ahmedabad, we have re-invented the production of snacks through this pioneering fryer making it consistent and efficient in quality. We are one of the leading companies in snack production technology with our Continuous Dal and Snacks Fryer fitted to suit all types of needs of the industry. The main peculiarities are the capability to keep the frying outcomes consistent as each kilo of daal and snack can reach the desired crispiness, texture, and flavour. The snack companies can trust this fryer to produce high quality snacks every time since it has a tight control over desired temperature and frying processes. It is an essential of our design, efficiency. Our fryer works round the clock and this helps in cutting down on downtimes, production efficiencies and the overall manufacturing process. The robotization of frying allows manufacturers to treat large batches without any difficulties and saves a lot of labor costs. We are food safety and product integrity conscious at Gungunwala.

Continuous Namkeen Fryer Manufacturer in India

Our Continuous Dal and Snacks Fryer is made with good quality, food grade material and comply with international safety and hygiene controls. The design of the fryer makes it very easy to clean and maintain and thus this further allows better food safety measures. Continuous Dal and Snacks Fryer by Gungunwala presents the most appropriate answer in a world where snack palates are diverse and includes people all over the world. Our fryer is a fryer that has both local regional taste and international snack needs. Our services ensure smooth export mechanisms as snack manufacturers can now extend their operations to the international market. We can select Gungunwala as a partner to produce snacks. Finding the snack products that will meet the expectations of consumers is guaranteed using our Continuous Dal and Snacks Fryer which offers efficiency, reliability, and innovation. Feel the future of snack manufacturing and take your production ability to another unprecedented level with Gungunwala.

Features of Continuous Multipurpose Dal Fryer :

| Model | CNF-250 | CNF-350 | CNF-500 |

| Production Capacity (Floating Products) | 250 Kg/Hr | 350 Kg/Hr | 500 Kg/Hr |

| Maximum Power Consumption | 7.5 HP | 8.5 HP | 11.0 HP |

| Edible Oil Holding Capacity | 490 Ltr | 600 Ltr | 950 Ltr |

| Automation Level | PLC – HMI | ||

| Product Detection Sensors | Attachment Available in all Models | ||

| Blancher | Attachable in all Models | ||

| Fryer Insulation | Fiber Glass Insulated Fryer Body (Minimizing Heat-loss) | ||

| Supported Products | All Floating and Non Floating Products | ||

| Auto Oil Level | Attachable in all Models | ||

| Width of Setup | 15 ft | ||

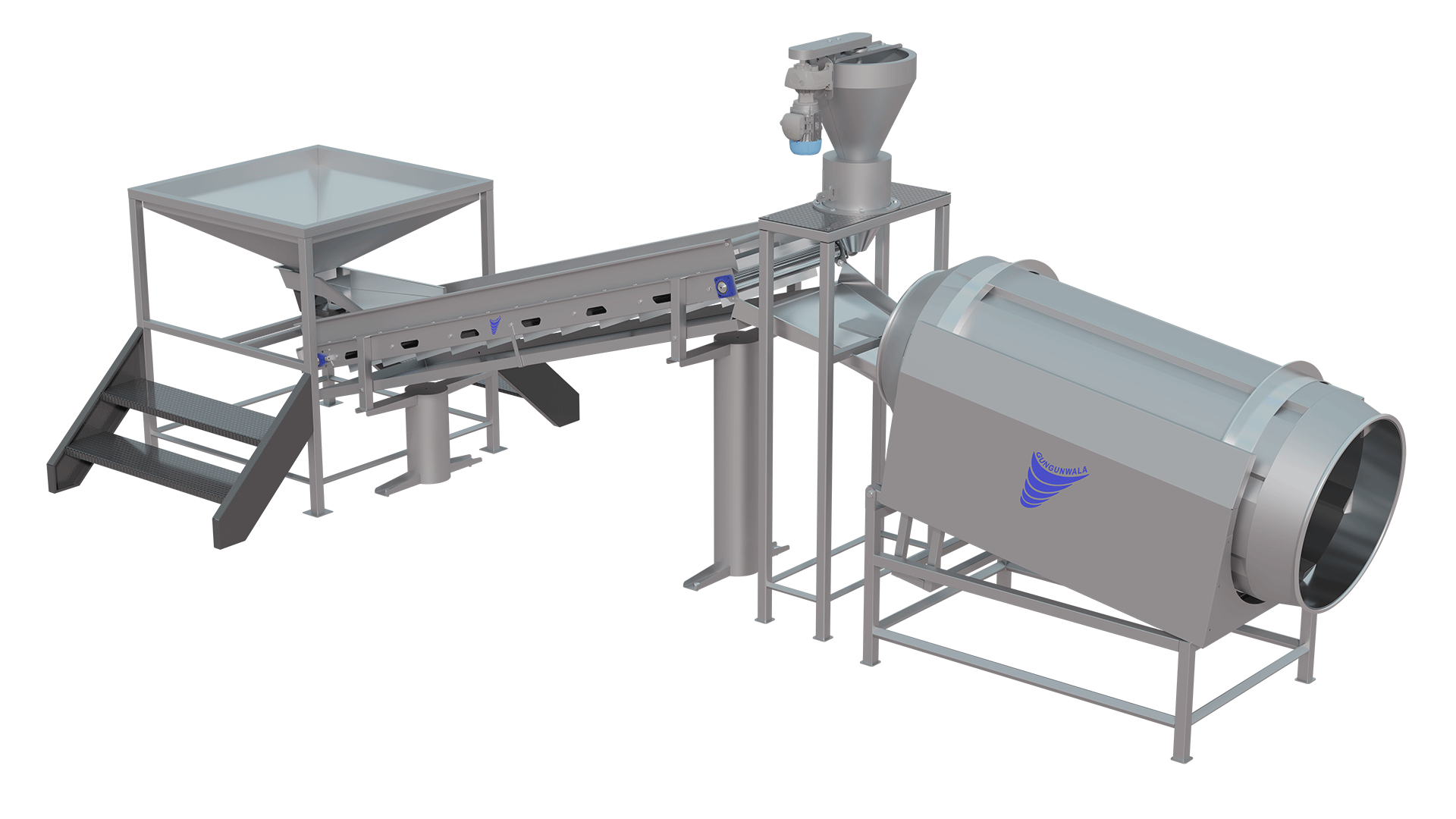

Advantages :

Why to choose Frying Solutions from GUNGUNWALA?

- Automation :- At GUNGUNWALA we have the most automated process ready with maximum automation, using various sensors, one of which is product detection sensors. This pledge to automation does not only mean that they will save a lot of electricity but also limits the dependence of manual labor which will ultimately lead to a deeper pocket in terms of operation as compared to our counterparts.

- Oil Filtration :- Excellence to a greater extent lies in the field of oil filtration. Our fryer is diaphragm-sealed with the Edible Oil Filter designed to be seamlessly installed on the fryer and is able to filter particles as tiny as 60 microns of oil. This increases the shelf life of your edible oil not just prolonging the shelf period but results in significant savings.

- Fryer Design :- With our vastness of experience in the industry and technical ability GUNGUNWALA prides itself in developing quality fryers. The machines have the lowest oil-holding capacity in the industry. Besides, our fryer will have a consistent temperature environment that will not fluctuate providing us with high-quality chips with minimum content of oil. So in a way our fryers will help you save valuable oil resource without you sacrificing the quality of your products.

Usage :

- Continuous Fryers are our creation that caters to the high production capabilities of industries wanting to make 2000 kg to 10,000 kg of Namkeen and snacks in a day. State-of-the-art technology, constant reliability, and dedication to the top-notch quality, these fryers grant you a chance to rise above the competition and make your brand an industry leader by enhancing your snack production.