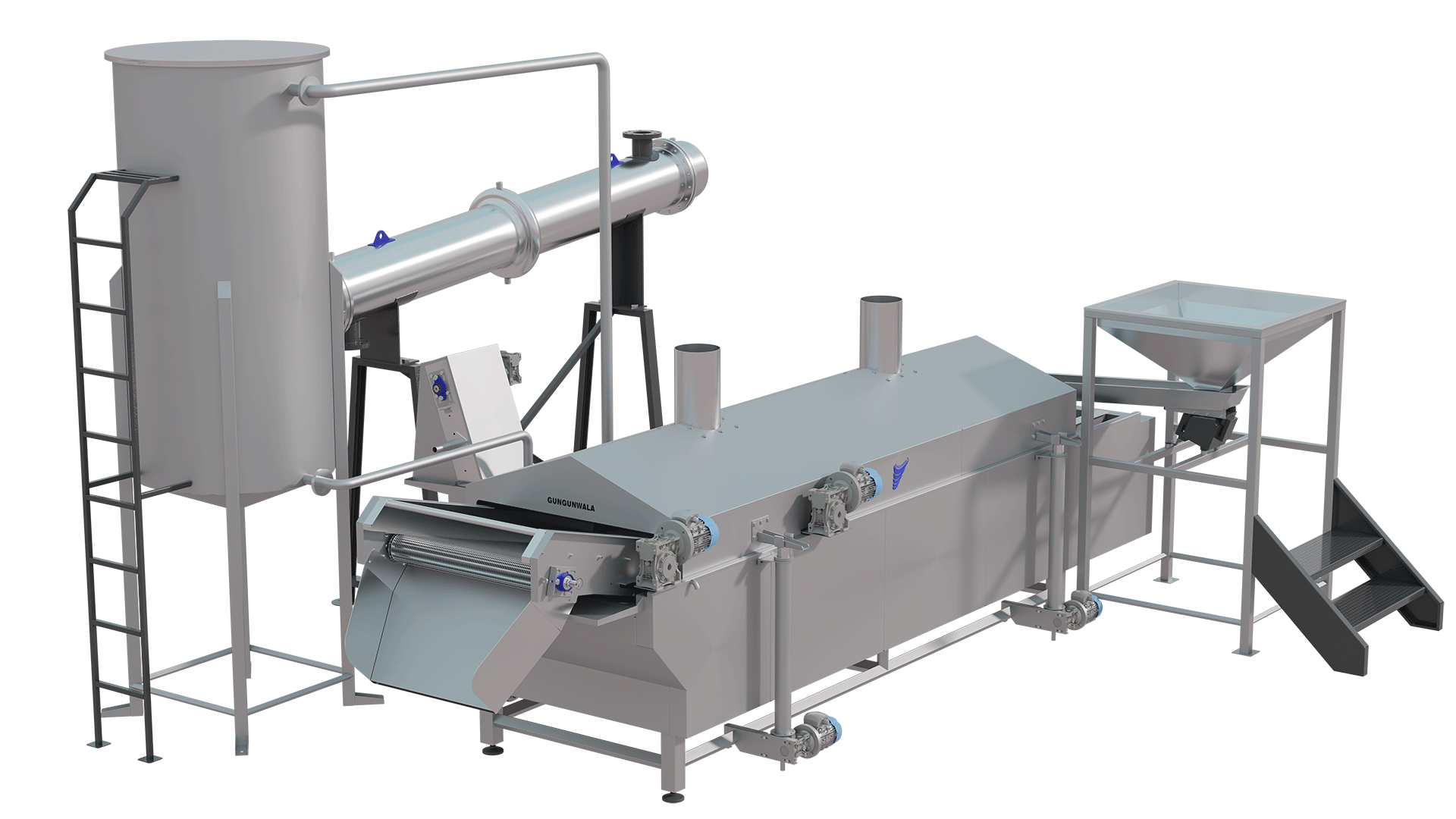

Multi Product Continuous Frying System - Energy & Cost-Efficient Food Production

Gungunwala, a renowned manufacturer, supplier and exporter practicing since Ahmedabad is pleased to introduce its first of the kind Continuous Namkeen Fryer. Our continuous fryer is an icon of innovation and quality because it was developed to be dynamic to accommodate the dynamic changes of the snack industry. Continuous Namkeen Fryer are used extensively to produce namkeens which is an elastic line of snack products. At Gungunwala, necessary expertise has been used to create a fryer that is exceptionally good in quality, efficiency and throughput. The difference between our Automatic Namkeen Fryer and the others is that we never waver in our aim to be able to achieve consistent frying outcomes. This fryer is equipped with a scientific temperature control system and the latest frying technology ensuring that each batch of namkeen is crispier, of the right texture and delicious. In snack manufacturers, the implication of this is snack products that regularly surpass and satisfy the consumer expectations. One of the main points of our design philosophy is efficiency.

namkeen making machine exporter in India

Continuous Namkeen Fryer

Our Continuous Namkeen Fryer is hassle free, minimising the need to stop and increase productivity. Automation of the frying procedure enables the manufacturers to engage in large scale production of namkeens and this goes a long way in saving on labour costs. Gungunwala uses quality products and stick to international safety and hygiene norms in the manufacturing process of our Continuous Namkeen Fryer so as to guarantee the safety of food and the integrity of product. As fryers, they not only reduce risks but are easily washed and cleaned, and they work to your advantage, given that food safety is guaranteed. In the fast-paced worldwide snack company, novelty and trust are unsurpassed. Continuous Namkeen Fryer manufactured by Gungunwala enables snack manufacturers to achieve these needs whether locally or the global arena. Our fryers are conveniently available globally as we offer all the assistance needed to perform a smooth export procedure. Find out the new generation of creating the best snacks with the Continuous Namkeen Fryer by Gungunwala. Become more at the top of your manufacturing process, produce more and maintain the top quality of your product with our advanced technologies in the frying industry. Make up your mind to join hands with Gungunwala and our technology will make your snack business fly high. Believe in our experience and skill and you will feel the difference.

Features :

| Model | CNF-250 | CNF-350 | CNF-500 | CNF-700 | CNF-1000 |

| Production Capacity | 250 Kg/Hr | 350 Kg/Hr | 500 Kg/Hr | 700 Kg/Hr | 1000 Kg/Hr |

| Maximum Power Consumption | 6.5 HP | 6.5 HP | 9 HP | 10 HP | 10 HP |

| Edible Oil Holding Capacity | 370 Ltr | 450 Ltr | 530 Ltr | 590 Ltr | 680 Ltr |

| Control System | PLC – HMI | ||||

| Product Detection Sensors | Attachment Available in all Models | ||||

| Fryer Insulation | Fiber Glass Insulated Fryer Body (Minimizing Heat-loss) | ||||

| Supported Products | All Floating Products | ||||

| Auto Oil Level | Attachable in all Models | ||||

| Warranty | 1 Year | ||||

| Other name | Namkeen Making Machine | ||||

| Installation Type | Free Stand | ||||

| Width of Setup | 15 ft | 16 ft | 17 ft | ||

Usage :

- Usage Intention : Industrial usage only

- Minimum Daily Production : 2000 Kg – 10000Kg

- Fried Products : Namkeen, Sev, other Floating products

- Fuel : Gas, Diesel, Pellets, Wood fired

Namkeen Plant Manufacturer

As a Namkeen Plant Manufacturer, we provide complete and dependable solutions for making a wide range of customary and modern namkeen snacks. Our namkeen plants are equipped with state-of-the-art technology which guarantees the same flavor, texture, and very efficient production. The plant built with food-grade stainless steel not only meets the strict hygiene standards but also a long life performance. Namkeen plant consists of the most important machines, like dough Mixer, extruders, fryers, seasoning systems, and cooling conveyors, all together in a way that they work smoothly and continuously. They are simple to operate and need less energy, thus our plants assist in reducing the cost of production while improving the quality of output. They cater to the needs of small, medium, and large-scale snack manufacturers as our namkeen plants can be tailored to capacity and product specifications. We, therefore, do not compromise on quality, safety, and productivity, and as such, we provide reliable solution for namkeen manufacturing that helps in business growth and maintenance of consistent product quality.

Automatic Namkeen Plant manufacturer

Being the manufacturer of an automatic namkeen plant, we are providing the complete automation to produce high-quality namkeen with maximum efficiency as well as consistency. The automatic plants are designed with state-of-the-art technology that takes care of the processes like mixing, forming, frying, seasoning, and cooling with only a little manual intervention. It guarantees the same taste, texture, and appearance in every batch. The automatic namkeen plant is made of food-grade stainless steel, and it conforms to the strictest hygiene and safety norms while being very durable at the same time. The system includes excellent temperature control, smooth material flow, and energy-wise operation, which lowers the production costs and waste. The operator-friendly controls make the operation easy and need very few manpower. Our automatic namkeen plants are perfect for the snack manufacturers of any size, and they can be tailored to the production capacity and the number of products. Our focus on productivity, reliability, and exceptional output quality makes it easier for businesses to grow and cope up with the ever-increasing market demand quickly.

Namkeen Fryer Machine

Being the manufacturer of an automatic namkeen plant, we are providing the complete automation to produce high-quality namkeen with maximum efficiency as well as consistency. The automatic plants are designed with state-of-the-art technology that takes care of the processes like mixing, forming, frying, seasoning, and cooling with only a little manual intervention. It guarantees the same taste, texture, and appearance in every batch. The automatic namkeen plant is made of food-grade stainless steel, and it conforms to the strictest hygiene and safety norms while being very durable at the same time. The system includes excellent temperature control, smooth material flow, and energy-wise operation, which lowers the production costs and waste. The operator-friendly controls make the operation easy and need very few manpower. Our automatic namkeen plants are perfect for the snack manufacturers of any size, and they can be tailored to the production capacity and the number of products. Our focus on productivity, reliability, and exceptional output quality makes it easier for businesses to grow and cope up with the ever-increasing market demand quickly.