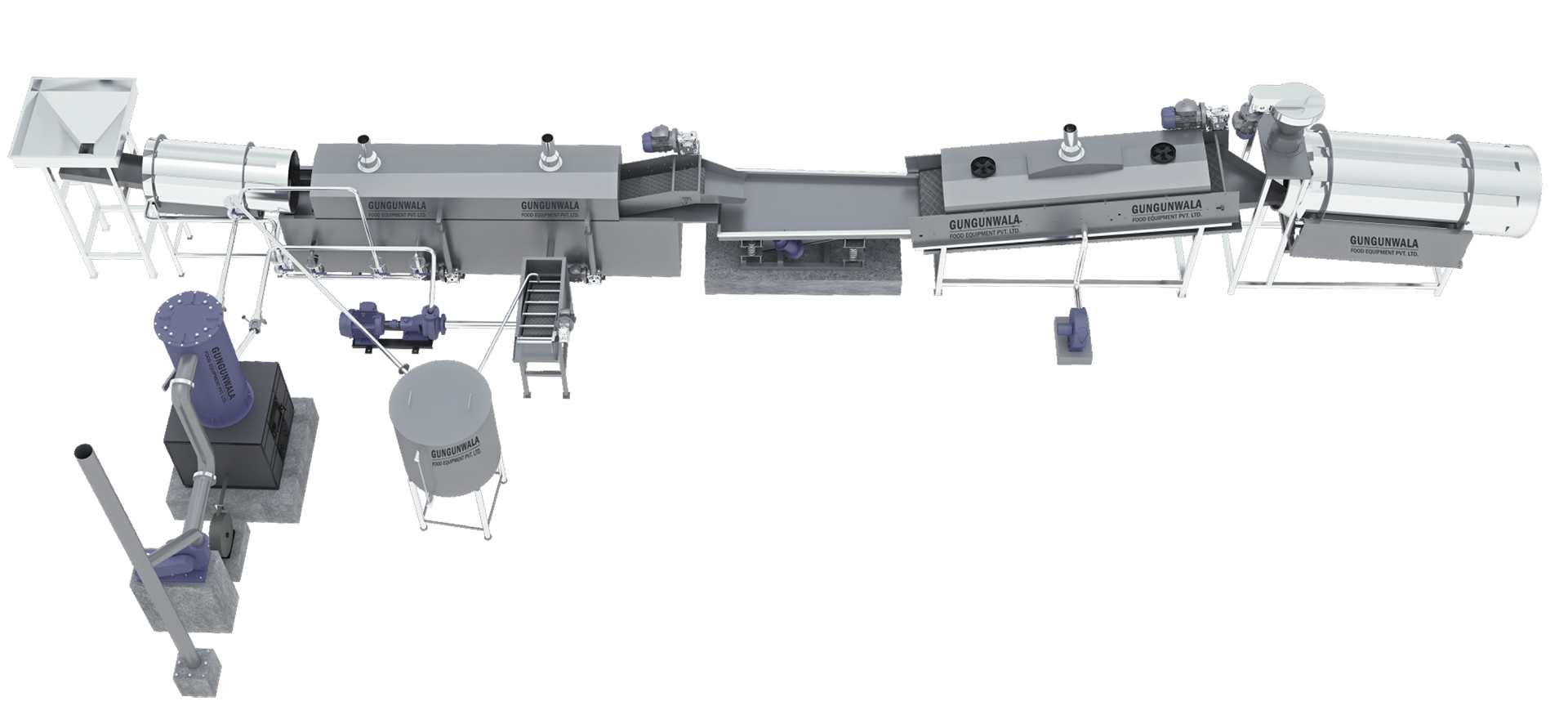

Gungunwala is the place where you will find excellence as far as innovation is concerned in the world of snacks. We are proud to introduce our Fully Automatic Fryums and Pellet Production Line as a testimony of our status as an Indian snack industry front-runner, manufacturer, supplier, and exporter. Our state of the art facility is located in the center of Ahmedabad and the place where ideas become crispy realities. With our Fully Automatic Fryums and Pellet Production Line, we transform the snack manufacturing. This highly sophisticated line has been designed to achieve a smooth operation of the whole production process. Everything is done perfectly, whether it is blending an ideal combination of ingredients and giving it the right shape, frying, and even seasoning.

Automatic Fryums and Pellet Production Line Manufacturer

The peculiarity of our production line is versatility. You can make your own fryums, or you can make your own innovative snacks with pellets, but you will find that our equipment is completely adaptable in both shape and flavor to an indefinite number. Customization is available in the line as you can play around with textures, sizes, and seasoning options. This flexibility means that your snacks will be different in the market. Our production is based on quality. We observe high standards in the international laws and standards and therefore all the fryum and pellets that come out of our plant are of the best quality. Our hygiene and food safety standards are uncompromising, whereby you get the snacks that are not only tasty but also reliable.

The Fully Automatic Fryums and Pellet Production Line is at Gungunwala which is designed to be efficient. It is the most productive because it involves little manual adjustments, and the product remains consistent and with minimum wastage. Its user-friendly interface provides control over the user and you can monitor and modify production parameters in real-time. Being a responsible exporter, we manage the whole process of production to packaging whereby all the products are delivered to their destinations in their original condition. Our snacks are good and our customers all over the world cherish us. Our Fully Automatic Fryums and Pellet Production line also gives an expression of our excellence, taste and innovation. Be with us and we will take you on a tasting trip that is a pleasure to the palate of consumers all over the world.

Our production line is different as it is versatile. Our equipment can take infinite forms and flavors, whether you are making fryums in the traditional fashion or developing a new type of pellet snack. The line also includes customization, which gives you the opportunity to test textures, sizes, and the profiles of seasoning. This will give you flexible snacks in a competitive market. Our production is based on quality. We are bound by the strict international standards, and we make sure that all the fryum and pellets out of our doors are of the best quality. We are devoted to the hygiene and food safety and offer you not only tasty snacks but also reliable ones.

The Fully Automatic Fryums and Pellet Production Line of Gungunwala is output efficient. It is the most effective means of maximizing productivity as there is a minimum of human involvement resulting in steady output with minimum wastage. The user-friendly interface will enable you to control things, and monitor and change production parameters in real-time. Being a responsible exporter, we will ensure that we control the whole process, including production and packaging of products until we deliver them to the market, at their best condition. Our international customers believe in us on the quality of our snacks and their reliability. Our Fully Automatic Fryums and Pellet Production Line demonstrates our focus on the excellence, taste and innovation. Then come with us and have a taste experience that will quiet taste buds across the world.

Features :

| Model | FA-FPL-300 | FA-FPL-500 | FA-FPL-1000 |

| Production Capacity (Fried Fryums) | 300 Kg/Hr | 500 Kg/Hr | 1000 Kg/Hr |

| Total Heat Load | 1.5 Lk Cal | 2.0 Lk Cal | 3 Lk Cal |

| Maximum Power Consumption | 13 HP | 14 HP | 16 HP |

| Edible Oil Holding Capacity | 320 Ltr | 350 Ltr | 430 Ltr |

| Total Length of production Line | 47 feet | 47 feet | 50 feet |

| Automation Level | PLC – HMI | ||

| Product Detection Sensors | Attachment Available in all Models | ||

| De oiling Mechanism | De-Oiling Vibrator or Online Hydro Both Attachable | ||

| Fryer Insulation | Fiber Glass Insulated Fryer Body (Minimizing Heat-loss) | ||

| Supported Products | Fryums, Extruded Snacks (Kurkure) | ||

| Auto Oil Level | Attachable in all Models | ||

| Width of line | 14 feet | 15 feet | 16 feet |

Advantages :

Why to choose Frying Solutions from GUNGUNWALA?

- Automation : - At GUNGUNWALA, we pride ourselves on offering the highest level of automation in this industry segment. Our cutting-edge automation systems leverage a variety of sensors, including product detection sensors, to optimize operations. This level of automation not only leads to significant electricity savings but also reduces reliance on manual labour, resulting in a substantial decrease in the operational costs of our production lines compared to our competitors.

- Oil Filtration : - At GUNGUNWALA, we take pride in offering the highest level of oil filtration in our industry segment. Our Edible Oil Filter, integrated with our fryer, is capable of effectively removing particles as small as 60 microns from the oil. This advanced filtration system significantly extends the usable life of edible oil, resulting in substantial cost savings. Feedback from our long-standing customers who have integrated this filter into their production lines speaks volumes; they have reported a significant increase in the lifespan and quality of their fried products. Upon careful calculation, these improvements have translated into substantial savings on oil costs for our customers.

Usage :

- Usage Intention: Industrial usage only

- Minimum Daily Production : 3000 Kg – 10000Kg Fryums and Pellets

- Flavor Application : Automatic

- De-oiling and Cooling : Automatic

- Fuel : Pellets, Gas, Diesel, Wood Fired