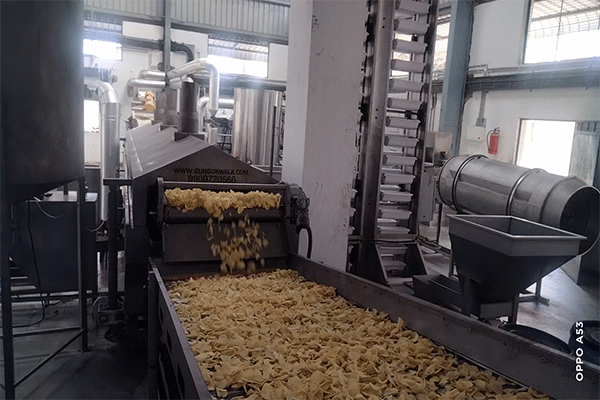

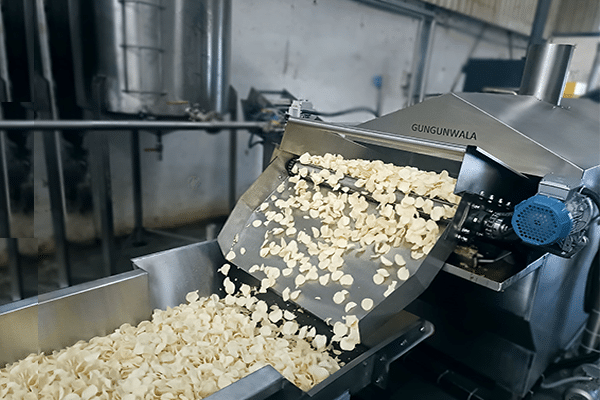

The snack industry finds its excellence symbol in Gungunwala which operates at the core of Ahmedabad. The Semi Automatic Potato Chips Production Line at Gungunwala delivers outstanding manufacturing excellence. Through their precision slicing system the factory converts potatoes into uniform delightful crisps which ensure all chips maintain a dependable crunch that creates separation from other brands. The exceptional nature of Gungunwala’s production line emerges from merging efficiency with flexible operation. The semi automatic potato chips production line contains multiple features that allow creators to make traditional classic chips as well as innovative gourmet options. Operators maintain complete machine access which lets them perform real-time modifications for meeting various market needs. The quality assurance principles are consistently present throughout all operations. Wash and peel and frying and seasoning procedures maintain strict hygiene protocols which deliver both excellent taste quality along with peak safety measures for consumers.

Potato chips plant manufacturer

The interface offers hassle-free operation which enables staff members to manage chip-cutting variability and set cooking temperature levels precisely. The advanced Semi Automatic Potato Chips Production Line exists with both powerful functions and efficient facility space organization. The quality standards of Gungunwala’s machinery extend around the globe because their technology originates from domestic manufacturing knowledge. Every chip produced at Ahmedabad comes from facilities in this city and represents both its culinary heritage and technological advancement that ensures superior quality taste and innovation. Selecting Gungunwala’s a leading manufacturer, supplier, and exporter allows you to partner with a company that turns basic potatoes into stunning chips through systematic processing.

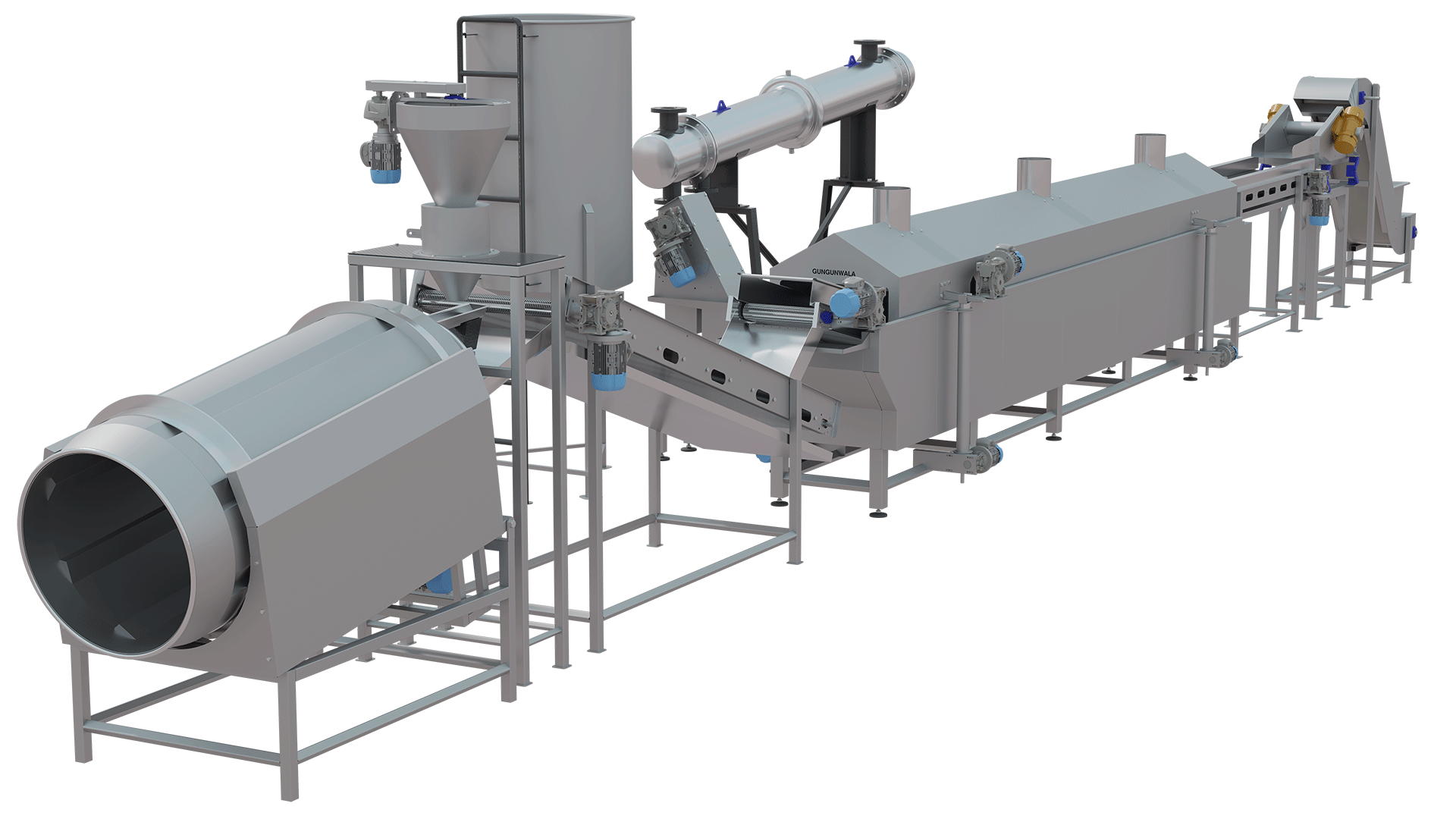

Features of Semi Automatic Potato Chips Production Line

| Model | SA-PCL-100 | SA-PCL-200 | SA-PCL-300 |

| Production Capacity (Finished Chips) | 100 Kg/Hr | 200 Kg/Hr | 300 Kg/Hr |

| Total Heat Load | 2 Lk Cal | 4 Lk Cal | 5 Lk Cal |

| Maximum Power Consumption | 19 HP | 20 HP | 22 HP |

| Edible Oil Holding Capacity | 480 Ltr | 580 Ltr | 670 Ltr |

| Total Length of production Line (Without Blancher) | 55 feet | 55 feet | 55 feet |

| Automation Level | PLC – HMI | ||

| Product Detection Sensors | Attachment Available in all Models | ||

| Blancher | Attachable in all Models | ||

| Fryer Insulation | Fiber Glass Insulated Fryer Body (Minimizing Heat-loss) | ||

| Supported Potato Products | Plain Chips, Ruffles Chips and Potato Sticks | ||

| Auto Oil Level | Attachable in all Models | ||

| Width of line | 15 feet | 16 feet | |

| Weight | Based on Models | ||

Advantages :

Why to choose Frying Solutions from GUNGUNWALA?

- Automation : - We Offer highest level of automation in this segment utilizing all kinds of different sensors such as product detection sensor, etc. Result of using this level of automation results in saving electricity and decreasing the dependency on manual labor which results in decreasing the operation cost of the production line compared to any other competitors.

- Oil Filtration : - Highest Level of oil filtration is offered by us in this segment, Our Edible oil Filter attached to fryer can filter particles up to 60-Microns in size from the Oil. This filters helps in increasing the useable life of Edible oil which results in saving Edible oil. After attaching this filter in production line, our older customers reported that the life of Edible oil is increase by 12 hours. After calculation, this resulted in saving huge amount of oil of the customers.

- Fryer Design : - With huge amount of experience of this Industry and Machines, We GUNGUNWALA have successfully developed our fryers which has the lowest oil Holding capacity possible within the industry. Even temperature within our fryer does not drop, this results in high quality chips with low oil content ultimately saving oil of the user.

- Service Backup :- We have strong and highly experienced team of service engineers who are always ready to solve any issue within the system minimizing the downtime of our Production Line.

Usage :

- Usage Intention: Industrial

- Minimum Daily Production : 1000 Kg – 3000Kg Potato Chips

- Flavor Application : Automatic