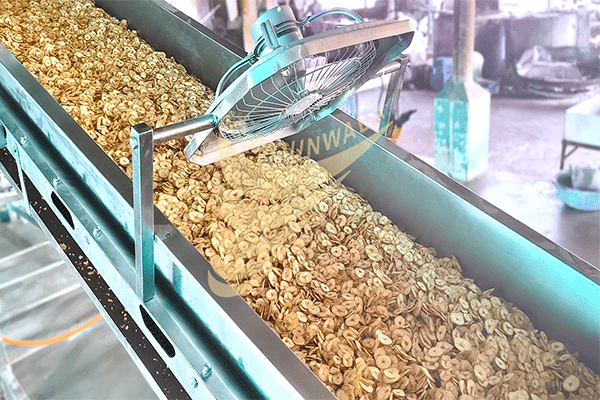

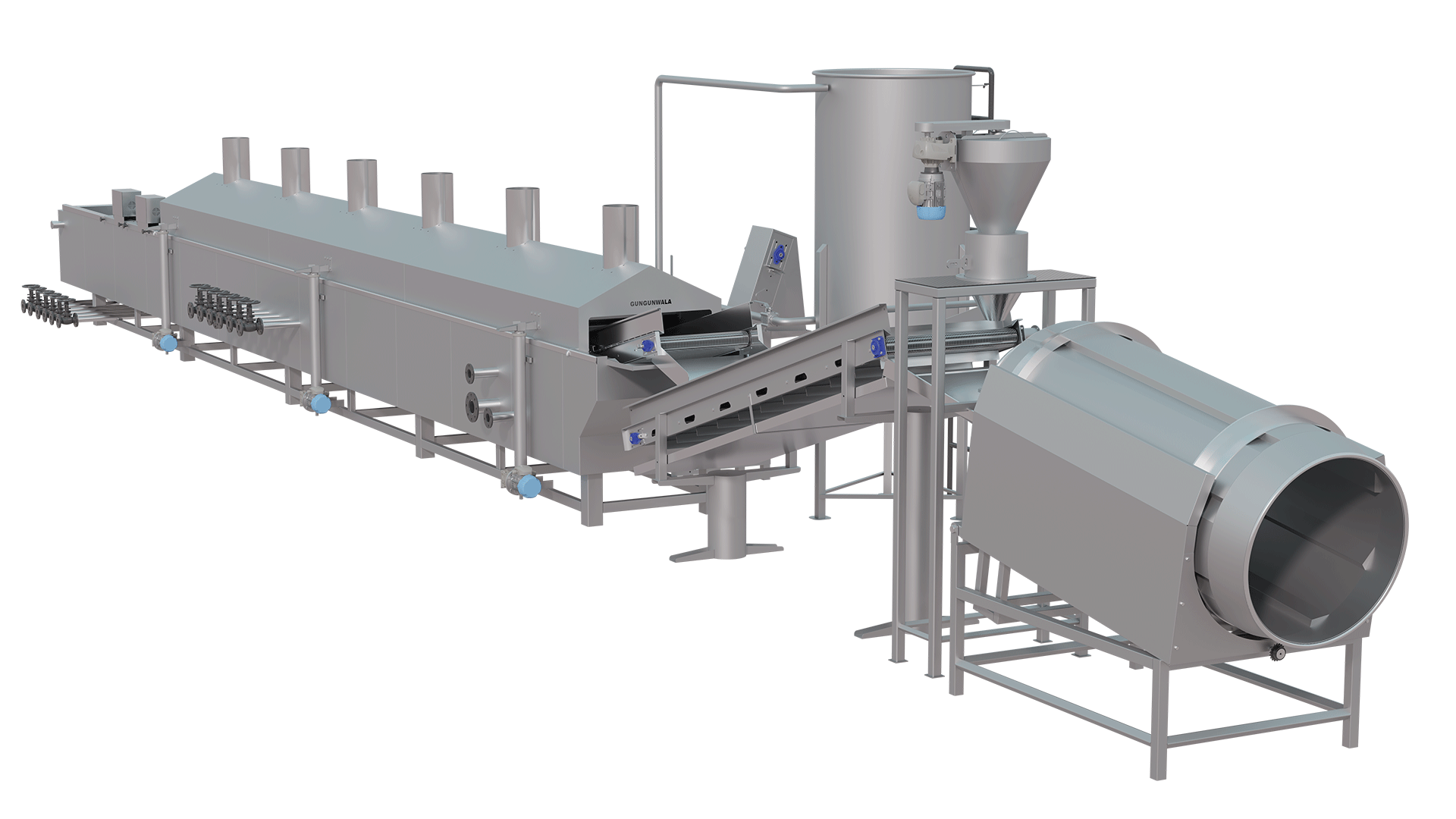

An exclusive Banana Chips Production Line is introduced by Gungunwala as a sign of our excellence as a manufacturer, a supplier, and an exporter in the world of snacks. Our modern plant is located in Ahmedabad and is very innovative with quality. Our Banana Chips Production Line is carefully designed to make our simple bananas into crunchy, tasty objects of desire. The line perfectly calibrates the innovative technology with the old-school art because, in this way, each chip has kept the natural sense. The consistency and quality are maintained as peeling and slicing are supervised thoroughly. The thing is that our production line is flexible. Do you like regular salted chips or any other flavored chips? our equipment has no trouble with multiple recipes. They allow operators to control the thickness of slicing and frying period accurately so that there is an excellent batch each time.

Usage :

- Usage Intention: Industrial

- Minimum Daily Production : 1200 Kg – 3500Kg Banana and Plantain Chips

- Flavor Application : Automatic

- Blanching : Automatic

Banana Chips Plant Manufacturer

We, as the major manufacturer of banana chip plants, manufacture end-to-end banana chip plant solutions for manufacturing high-quality banana chips efficiently and in hygienic conditions. The snack food processing industry is ever-changing with increasing demand, and our state of the art banana chip processing machinery has been built to be consistent, productive and of a high quality. Our automated banana chips factory covers many specifications, such as cutting fresh bananas, frying, seasoning and packing banana chips, which makes the production simple, economical and in line with the domestic and international standards. Our banana chips factory is fitted with modern equipment like banana cutters, fryer machines, oil collectors, mixers and high-pressure food packaging machines which were made using food-grade stainless steel materials that are durable and hygienic. All the machines in the plant are designed based on the energy-efficient criteria and small amount of oil retention, which means crispy golden chips and long shelf life. Our modular and customizable banana chips processing line can suit a small startup or a large-scale manufacturer and can be optimized depending on the capacity and the output you need.

Banana Chips Line manufacturer in India

Features :

| Model | BCL-100 | BCL-200 | BCL-300 |

| Production Capacity (Finished Chips) | 100 Kg/Hr | 200 Kg/Hr | 300 Kg/Hr |

| Total Heat Load | 2 Lk Cal | 4 Lk Cal | 5 Lk Cal |

| Maximum Power Consumption | 14 HP | 16 HP | 18 HP |

| Edible Oil Holding Capacity | 480 Ltr | 580 Ltr | 700 Ltr |

| Total Length of production Line (Without Blancher) | 50 feet | 50 feet | 55 feet |

| Automation Level | PLC – HMI | ||

| Product Detection Sensors | Attachment Available in all Models | ||

| Fryer Insulation | Fiber Glass Insulated Fryer Body (Minimizing Heat-loss) | ||

| Supported Banana Products | Round, Oval, Long (Capacity may change based on shape) | ||

| Auto Oil Level | Attachable in all Models | ||

| Width of line | 15 feet | 16 feet | |

Advantages :

Why to choose Frying Solutions from GUNGUNWALA?

- Automation : - We Offer highest level of automation in this segment utilizing all kinds of different sensors such as product detection sensor, etc. Result of using this level of automation results in saving electricity and decreasing the dependency on manual labor which results in decreasing the operation cost of the production line compared to any other competitors.

- Fryer Design : - With huge amount of experience of this Industry and Machines, We GUNGUNWALA have successfully developed our fryers which has the lowest oil Holding capacity possible within the industry. Even temperature within our fryer does not drop, this results in high quality chips with low oil content ultimately saving oil of the user.

- Service Backup :- We have strong and highly experienced team of service engineers who are always ready to solve any issue within the system minimizing the downtime of our Production Line.

- Small Particle Rejection : - Our system is designed in a way that, small wastage and fine particles are will be rejected before entering the fryer. This helps in maintain quality of Edible oil and produced plantain and banana chips.

Banana Chips Fryer Machine Manufacturer

As a manufacturer of banana chip fryer machines, we provide cutting-edge and effective frying solutions made especially for creating crispy, premium banana chips. Every batch produced by our machines will have consistent flavour, optimal oil absorption, and uniform frying. The fryer machines are perfect for both small-scale units and large commercial snack production facilities because they are made of premium-grade stainless steel, which guarantees excellent durability, easy cleaning, and complete compliance with food safety standards. To maintain ideal frying conditions, our banana chip fryer machines are built with accurate temperature control and effective heating systems. This cuts down on oil usage and production time while maintaining the banana chips’ original flavour, colour, and crunch. The machines guarantee seamless and continuous operations because they are simple to use, energy-efficient, and require little maintenance. These devices can handle large production volumes without sacrificing quality, making them appropriate for batch and continuous frying processes. Our fryer machines offer dependable performance and superior output, whether you are launching a banana chip manufacturing company or improving your current setup. Our banana chip fryer machines are the best option for contemporary snack food manufacturers because they prioritise productivity, hygiene, and long-term value.

Banana Chips Fryer

An essential tool for making crispy, uniformly fried banana chips is a banana chip fryer. This fryer’s consistent performance guarantees even heating and regulated frying temperature, producing superior chips with superior flavour, colour, and texture. The banana chip fryer is made of food-grade stainless steel, which upholds hygienic standards and provides long-lasting durability for frequent use. The fryer’s effective heating systems minimise oil usage while preserving ideal frying conditions. Both small businesses and large snack manufacturers can benefit from its simple operation and low maintenance requirements. Because of its sturdy design, it can manage large production volumes without compromising the quality of the final product. A banana chip fryer is perfect for commercial food processing facilities because it increases output, minimises manual labour, and produces reliable results. It is a dependable option for companies trying to make high-quality banana chips more profitably and efficiently.